6 signs your plumbing equipment required PCB replacement

Plumbing systems are an essential component of any household or commercial establishment. Often, we take for granted the intricate workings of our plumbing equipment until something goes wrong. One crucial element that plays a significant role in the functionality of plumbing systems is the PCB, or printed circuit board. This article outlines the signs that indicate your plumbing equipment may require PCB replacement, ensuring that you stay informed to preempt costly repairs and inconveniences.

Understanding the role of PCB in plumbing equipment

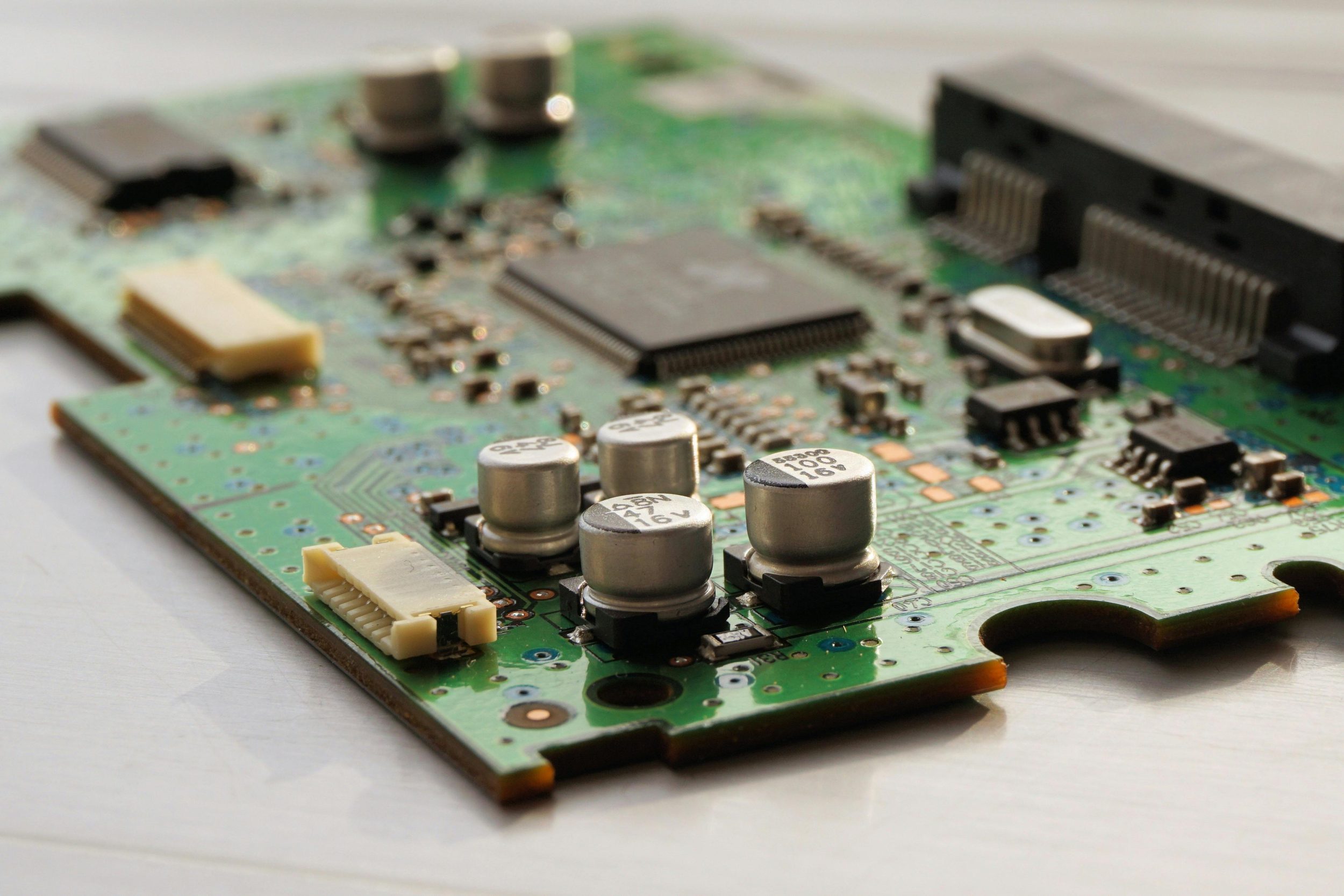

The printed circuit board (PCB) serves as the brain of many modern plumbing systems, particularly those that incorporate electronic components. This microprocessor-driven technology allows for improved efficiency and responsive management of water flow and temperature. The PCB processes various sensor inputs and regulates the operation of pumps and water heaters, thereby enhancing the overall functionality of the plumbing system.

A well-functioning PCB contributes to better energy management, reducing unnecessary energy consumption and consequently lowering utility bills. It is an essential component that not only maximises performance but also extends the lifespan of plumbing equipment.

The function of PCB in plumbing systems

The PCB controls the main functions such as monitoring temperature settings, detecting leaks, and controlling water pressure. It ensures that the system operates within specified parameters, relaying important information to the user through displays and alarms. Additionally, the PCB can run diagnostics, informing the homeowner of any potential issues before they escalate into more significant problems.

Moreover, the PCB allows for automated responses to various changes in the plumbing system, ensuring timely adjustments in water flow and temperature. This sophisticated level of control is crucial for optimising the performance and reliability of plumbing equipment. For instance, in the event of a detected leak, the PCB can immediately shut off the water supply, preventing further damage and saving on costly repairs. Such proactive measures not only safeguard the property but also provide peace of mind to homeowners, knowing that their plumbing system is equipped with advanced technology that prioritises safety and efficiency.

The importance of maintaining your PCB

Keeping the PCB well maintained is critical, not just for the sake of functionality, but also for safety. A malfunctioning PCB could lead to hazardous situations such as overheating, which may damage other components of the plumbing system or even result in water damage in your home. Therefore, regular maintenance can help identify any developing issues with the PCB early on, ensuring efficient operation and minimising repair costs.

It is advisable to schedule periodic inspections and maintenance checks by professionals who are well-versed in plumbing equipment. Adhering to these practices not only extends the life of the PCB but can also improve the overall efficiency of your plumbing systems. Furthermore, many modern PCBs are designed with user-friendly interfaces that allow homeowners to monitor their systems closely. By staying informed about the performance metrics displayed, users can take proactive steps to address any anomalies, ensuring that their plumbing systems remain in optimal condition. This level of engagement not only fosters a sense of responsibility but also enhances the overall user experience, making plumbing systems more accessible and manageable for everyone.

Recognising the signs of a failing PCB

Knowing the indicators of a failing PCB in your plumbing equipment is essential for timely intervention. By recognising these signs early, you can take steps to prevent further damage and costly repairs. Here are three primary signs that you should be on the lookout for.

Unusual noises from your plumbing equipment

One of the first symptoms of a failing PCB is the emergence of unusual noises from your plumbing equipment. These sounds could range from odd clicking or buzzing to more alarming banging or hissing. Such noises often indicate that the PCB is struggling to manage the components effectively, which could signal impending failure if not addressed promptly.

If you start to notice these unusual sounds, it is crucial to investigate the source, as it may point to a malfunctioning PCB. Ignoring these signs can lead to more significant electrical or mechanical problems, causing interruptions in your plumbing system. In some cases, these noises may also be accompanied by vibrations or a feeling of heat emanating from the equipment, further indicating that something is amiss. Regular maintenance checks can help catch these issues early, allowing for a more straightforward resolution before they escalate into major repairs.

Inconsistent water temperature

Another indicator of a failing PCB is irregular water temperatures. If you find that your hot water supply is lukewarm one minute and scorching the next, it could mean that the PCB is not accurately regulating the temperature. A malfunctioning PCB may cause the water heater to turn on and off erratically, leading to erratic temperature fluctuations.

This inconsistency can be quite troublesome, especially in households where temperature control is essential for comfort and hygiene. If you are experiencing these fluctuations, examining the PCB for potential issues should be a priority. Additionally, it is worth noting that inconsistent water temperatures can also affect the efficiency of your heating system, leading to increased energy consumption and higher utility bills. Therefore, addressing PCB issues not only enhances comfort but also contributes to a more energy-efficient home.

Frequent equipment malfunctions

Repeated breakdowns or malfunctions of your plumbing equipment might be attributed to a failing PCB. If your system repeatedly trips, shows error codes, or fails to operate as intended, it may indicate that the PCB is no longer functioning correctly. Regular equipment failures can lead to a cascade of problems, raising the costs associated with repairs and increasing your stress levels.

Having a qualified technician analyse the PCB can help determine whether it requires replacement or if other components might be the primary culprits behind your plumbing issues. Furthermore, it is advisable to keep a log of any malfunctions or irregularities you observe; this information can be invaluable to the technician in diagnosing the issue. By being proactive and documenting these occurrences, you can contribute to a more efficient repair process, potentially saving both time and money in the long run.

The process of replacing a PCB in plumbing equipment

If you have identified signs that your plumbing equipment’s PCB is failing, the next step is to understand the process of replacement. While some may consider tackling a PCB replacement as a DIY project, it is essential to acknowledge when to call in the professionals.

When to call a professional for PCB replacement

When you notice persistent symptoms of a failing PCB, it is often best to seek professional help immediately. Licensed plumbers or technicians possess the skills and tools necessary for safely removing and replacing PCBs. Moreover, they can properly diagnose other underlying issues that may be compromising the overall system.

Attempting to replace a PCB without adequate experience can lead to further complications, including potential electric shocks or damage to other components. Therefore, engaging a professional is usually the most prudent course of action for both safety and efficiency.

The potential risks of ignoring a faulty PCB

Ignoring the signs of a failing PCB can not only lead to more extensive damage to your plumbing system but can also pose safety hazards. A malfunctioning PCB could cause overheating, leaks, or even fires in extreme cases. Additionally, prolonged negligence may result in a total system failure, leading to costly repairs or replacements.

The risks of ignoring a faulty PCB far outweigh the initial inconvenience of addressing issues early. By staying vigilant and reactive to malfunction indicators, you preserve both the integrity of your plumbing system and the safety of your home.

Maintaining your plumbing equipment post-PCB replacement

Once you have successfully replaced the faulty PCB, ongoing maintenance becomes vital to ensure optimum performance. Establishing a routine maintenance schedule can significantly improve the longevity and reliability of your plumbing equipment.

Regular checks for optimal performance

Conducting regular checks of your plumbing system, particularly the PCB, can help identify early signs of wear and tear. This includes examining the wiring, confirming that connections are secure, and ensuring that the unit remains clean and free of dust and debris.

Additionally, inspecting water temperature settings and monitoring the frequency of equipment malfunctions can provide insights into the ongoing health of your plumbing systems. By establishing such a regimen, you maintain higher performance levels and reduce the chances of unexpected failures.

Preventive measures to prolong PCB life

Implementing preventive measures is key to prolonging the lifespan of your new PCB. This can include maintaining moisture levels around your plumbing equipment, as excess moisture can lead to corrosion and damage over time. Furthermore, investing in quality surge protectors can shield your PCB from electrical fluctuations, which are often the culprits behind many electronic failures.

Regular professional maintenance checks should also be a part of your strategy. Technicians can identify potential issues earlier, ensuring that your plumbing system operates seamlessly.

Concluding thoughts on PCB replacement in plumbing equipment

In summary, understanding the signs of a failing PCB is crucial for effective maintenance and timely replacements. Being aware of unusual noises, inconsistent water temperatures, and frequent equipment malfunctions can help you act swiftly to prevent extensive damage.

The long-term benefits of timely PCB replacement

The long-term benefits of timely PCB replacement cannot be overstated. By addressing issues proactively, you enhance the longevity and efficiency of your plumbing equipment while ensuring the safety of your home. Investing time and resources into maintaining your plumbing system not only provides peace of mind but also leads to reduced costs associated with major repairs.

The cost implications of PCB replacement

The cost implications associated with PCB replacement can vary widely depending on the complexity of your plumbing system and the particular equipment involved. However, it is generally less costly to replace a PCB than to ignore early signs of malfunction, which can lead to far more severe and expensive issues.

By prioritising the health of your plumbing equipment and staying vigilant, you secure significant long-term savings while ensuring optimal performance. Ultimately, understanding and acting on the signs of PCB failure will lead to a more efficient, safe, and reliable plumbing system.